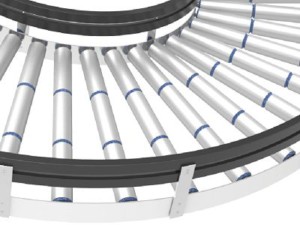

NEXUS GRAVITY ROLLER SPIRAL CONVEYOR

NEXUS Gravity Roller Spiral Conveyor is the perfect solution for the downwards transportation of cartons, plastic crate/box and other rigid packaging items. The high-quality unpowered rollers are installed on the whole conveyor to achieve gentle transportation of product without power consumption.

FEATURES

Zero Power Consumption

NEXUS Roller Spiral is not driven by a motor. Products slip down via rollers smoothly and make perfect declined transportation. Without power consumption, it is the most eco-friendly solution.

Flexible Customization

The width of the track and the number of layers are customized. Multi-entry transportation can be also realized by sensors and other electronic controls. Roller spiral is the best solution for high-rise buildings. Extra tracks can be also added to improve throughput.

Low Maintenance

Due to the simplified structure of the frame, only simple & regular works of maintenance is required. This saves a lot of cost of labor and downtime.

Spacing Saving

No space will be wasted by the spiral transport solution. Compact structure saves a valuable footprint for your factory. SPACESPACESPACE

Reliable Load Capacity

No matter it is a light-/heavy-weight application, cartons and other containers can be conveyed by a gravity roller spiral conveyor smoothly and easily.

Specification

● Outer diameter: Depends on roller width

● Number of layers and angle: According to the design of NEXUS

● Height: Depends on the required height

● Configurations:

Material & Frame

● Mild steel painted is the standard material for gravity roller spiral conveyors, please specify if stainless steel material is required.

● 10 mm thickness HDPE is added on the side guard and serves as a friction-resist protective wall.

Color

Nexus classic color of the spiral conveyor (Highly recommend)

For other colors, please refer to the RAL color table and specify which color you prefer:

*Note: Different computer monitors may display color differently. If a specific color tone is required, please send us the color sample by post.

Brake

During transportation, the products on rollers will move toward the outer side and against the side guard naturally. With friction between the products and HDPE on the side guard, the speed of the product will slow down. An additional brake device is not needed.

Single Row Free Roller

The single-row is the standard type of roller. Advantages of it include low cost, short production time, and great flexible load capacity, etc. There is no limitation for the packaging of products (both soft and hard material). Light-duty/heavy-duty rollers with different diameters are available as options.

The single-row is the standard type of roller. Advantages of it include low cost, short production time, and great flexible load capacity, etc. There is no limitation for the packaging of products (both soft and hard material). Light-duty/heavy-duty rollers with different diameters are available as options.

Multiple Row Free Roller

Multi-row is not the standard type of roller. It also has advantages such as flexibility in load capacity and no limitation in the packaging of products(both soft and hard). Light-duty/heavy-duty rollers with different diameters are available as options.

Multi-row is not the standard type of roller. It also has advantages such as flexibility in load capacity and no limitation in the packaging of products(both soft and hard). Light-duty/heavy-duty rollers with different diameters are available as options.