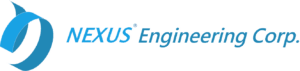

NEXUS Spiral Conveyor In High-Standard Food Production

We always believe that quality makes the difference, and we are happy to find our like-minded partners worldwide!It is an honor to be in part of the production line of Winston Nutritional, the leading manufacturer of dairy products and nutritional foods!-Production line of WN: https://lnkd.in/gBcTfBj-Factory acceptance test: https://lnkd.in/g5cjA8eE-mail: service@nexus-spiral.comWebsite: https://nexus-spiral.com/*Photo credit: Winston Nutritional#dairy #foodproduction #automation #spiralconveyor #logistics #nexusspiral

NEXUS Spiral Buffer- Project Portfolio

Nexus Buffer Spiral solves the downtime problems, and applied in various industries with its flexibility and durability. Below are some typical projects. Project 1 Industry: dairy processing Transported product: Bottled milk Spiral conveyor type: Dual- track spiral buffer Supply year: 2018 Video: https://youtu.be/eqQGrL-2B40 Project 2 Industry: beverage processing Transported product: canned coffee (Hot filled 80℃+) Spiral conveyor type: three-track spiral buffer Supply year: 2017 Video: https://youtu.be/scCh7cdkFzY Project 3: Industry: soap processing Transported Product: soap (Hot 50℃+) Type: single-track spiral buffer Supply Year: 2018 Video: https://youtu.be/c5-xRzef5f4 Visit NEXUS YouTube Channel [...]

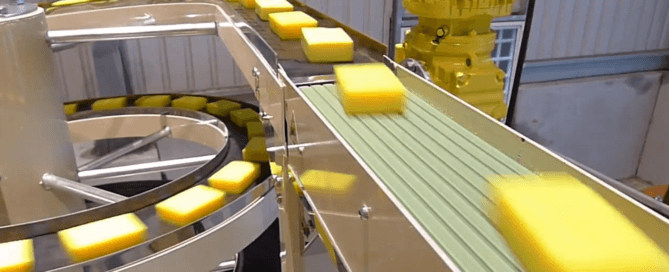

Multiple Inlet Gravity Spiral Conveyor

Last week we finished a gravity spiral conveyor with four inlets on different layer. Its total height is 16. 65 meters. SPACEGravity spiral conveyor is a good solution for downward transportation of products in rigid package, such as cartons and crates. (soft package may get stuck in gap between rollers). For products that are more than 10 meters high, roller spiral conveyors are the best choice.On gravity spiral conveyor with multiple inlets, it is necessary to avoid collision between products. To solve this problem, stop sensors are installed on each connecting conveyor. Electric control system would be also necessary if [...]

NEXUS Invites You to AUSPACK 2017 in Sydney

AUSPACK 2017 will take place in Sydney March 7th -10th, 2017. Our Australian partner will attend this exhibition and NEXUS Spiral conveyor is honored to be shown on our partner’s booth. We welcome you to visit stand 67 to see our spiral conveyor. NEXUS Spiral conveyor is focused to save place and cost for our customers. The standard Bi-directions spiral conveyor as NEXUS classic product will be shown at the exhibition. The conveying directions can be adjusted to be downward or upward according to your request.You can also check out our spiral conveyor video to find out about the diversity and [...]

The Role of Spiral Conveyor in Factory Automation

To remain competitive, many manufacturing/project managers and system integrators are facing challenges to improve productivity and efficiency, especially those with the high-volume pick, sort and pack requirements. To realize the goal, well-organized factory automation is fundamental. For these companies who turn to us for solution, the majority of them have invested in some material handling equipment, and the rest may only have basic self-contained complete equipment, more or less, they are troubled with various problems: Too many conveyors are all over the place, here and there, make the plant crowded and disordered. They are growing fast, however, the current conveyor [...]

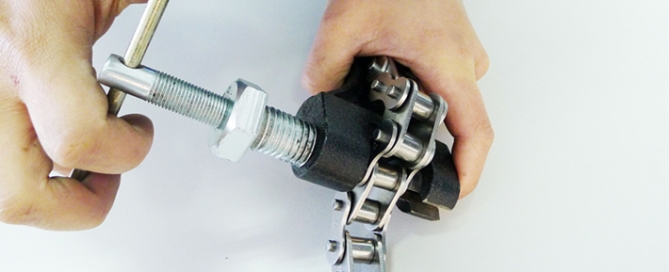

When Would You Need to Change A New Chain for Your Spiral Conveyor?

When do you need to change a new transmission chain in your spiral conveyor? The transmission chain of the spiral conveyor will be stretched in the process of operation, and you will have to change a new chain to ensure the smooth running of the spiral conveyor once the extension is up to its limits. Usually, there are two kinds of situations for the chain' elongation: Original elongation and abrasion elongation. Original elongation refers to the pre-stretching of new chains before delivery and it is the standard operating procedure. The new chains are stretched to maximum length to eliminate the [...]