NEXUS SPIRAL BUFFER CONVEYOR

WHY DO YOU NEED NEXUS SPIRAL BUFFER?

Nexus Buffer Spiral solves the downtime problems.

During production, (un)expected downtimes will happen in the front end of production lines. Such as breakdown of metal detection, label changing, the collapse of products, troubleshooting, etc.

Without a buffer conveyor, the only solution is to shut down the downstream machines/lines, and this usually brings huge losses.

Nexus Spiral Buffer is often set beside the top chain conveyor. When downtime happens, the products can be led into the spiral buffer for temporary and dynamic storage. After troubleshooting, the objects will be sent back to the original production line immediately without wasting time.

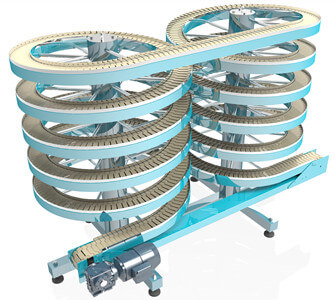

B Type Spiral Buffer Spiral

B-type spiral buffer is designed as a double-tower with continuous power. Straight in / Straight out is its main feature. It is the best solution for the production line that runs without suspension.

Recommended number of the layers is within 10. For the requirement of more storage capacity, we also provide a dual-power system. Each spiral has 10 layers, and totally two spirals have 20 layers. Nexus Miniature conveyor is mounted between two spirals to achieve the perfect transition.

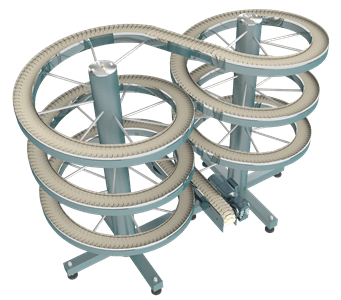

∞ Type Buffer Spiral

∞ type spiral buffer gives more flexibility to your layout of production. It breaks the limitation of linear planning and saves more space. However, the standard design of ∞ type spiral buffer is based on a single power.

The total number of layers is 10, double towers. Accordingly, please evaluate if its capacity of storage meets your needs.

Nexus spiral buffers are customized, consult our sales team service@nexus-spiral.com for solution.

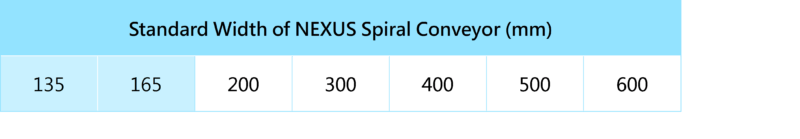

Specification

● The standard widths of the slat chains:

*Customized widths such as 700, 800, 900, 1000 mm, can be achieved by doubling the track.

*135 &165 mm are the standard widths of the narrow-track spiral conveyors.

*Other customized widths are also available, please clarify your needs by filling out the questionnaire.

● The maximum number of turns is 12. The maximum height of a spiral conveyor is 12 m.

● The maximum temperature in the contact zone between the conveyor belt and products is 50゚C.

Special heat-resistant materials are available, please contact us for more details.

● Inlet/outlet configurations:

Speed

The maximum speed of NEXUS Unit Load Spiral Conveyors is 60 m/min.

Load Capacity

The maximum load capacity of a spiral conveyor depends on the tensile force of the transmission chain.

the safe range of total load capacity of mild-steel transmission chain is within 1200 Kg, and the safe range of total load capacity of stainless-steel transmission chain is within 1000 Kg.

Material

Spiral conveyors material: Mild steel painted / Stainless steel

Transmission Chain material: Mild steel / Stainless steel

Color

Nexus classic color of the spiral conveyor (Highly recommend)

If you choose mild steel as the material for your spiral conveyor, and the above optional color solution is not suitable for you, in this case, a standard color appointed by you will be necessary for painting work.

Please refer to the RAL KT table below to confirm which color you prefer:

*Note: Different computer monitors may display color differently. If a specific color tone is required, please send us the color sample by post.