To remain competitive, many manufacturing/project managers and system integrators are facing challenges to improve productivity and efficiency, especially those with the high-volume pick, sort and pack requirements. To realize the goal, well-organized factory automation is fundamental.

For these companies who turn to us for solution, the majority of them have invested in some material handling equipment, and the rest may only have basic self-contained complete equipment, more or less, they are troubled with various problems:

- Too many conveyors are all over the place, here and there, make the plant crowded and disordered.

- They are growing fast, however, the current conveyor system is inefficient and can’t handle the volume, especially during peak times.

- In some production procedures, such as pick, sort, etc, too many workers are needed to finish the job, with low efficiency but high labor cost.

- To improve efficiency and drive cost reduction of storage is badly needed. With packed products (cartons/bags/tray) everywhere, but going nowhere, they can’t be moved to a storage area in time, so always occupy the production region.

- The maintenance cost of old equipment increases year by year.

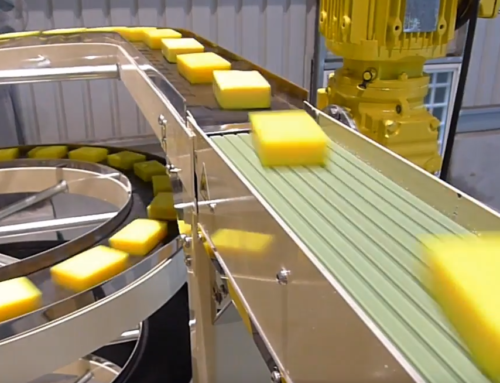

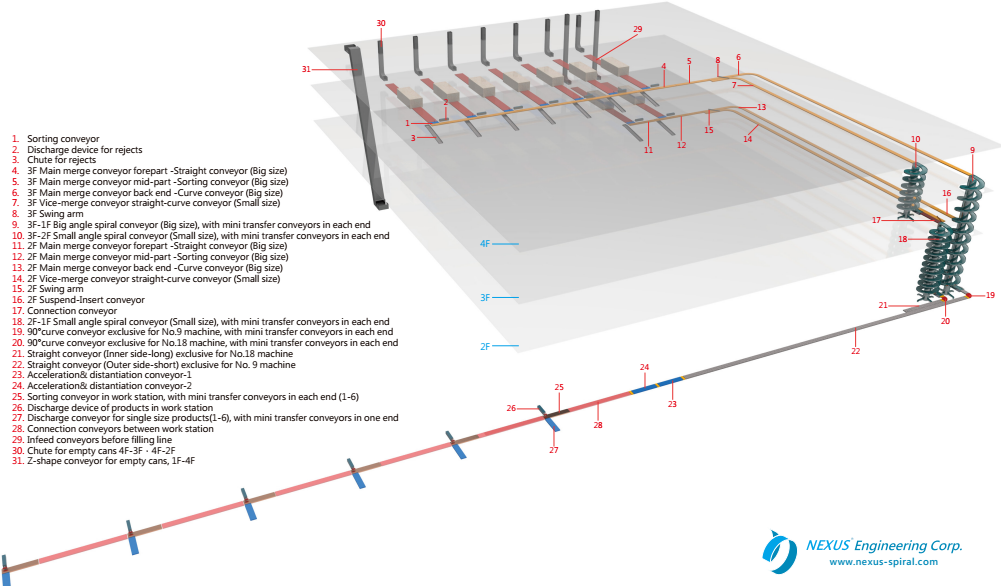

There is a very typical case that we met in the past. It is an edible oil processing factory, they have requirements for the whole automation system after filling, including product weighing, sorting, merging, classification, etc.

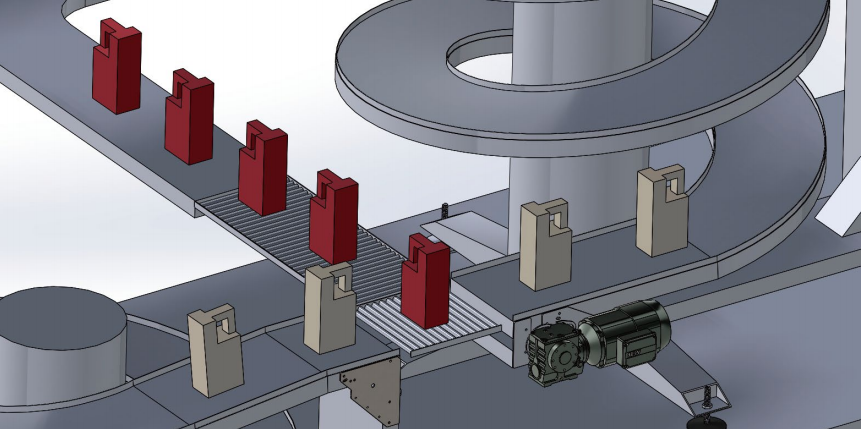

Material handling system in it takes absolute proportion, and the biggest challenge they meet is to transport bottles in different floors (3F, 2F & 1F) to the ground floor for storage. After comprehensive balance and accurate calculation, in the plant planning, three downwards spiral conveyors are set to achieve smooth downwards transportation of buckets, then classify them in the last step.

In a multi-floors manufacturing building, the spiral conveyor is the best solution to achieve transportation in the vertical direction, whether single inlet/outlet or multi inlet/outlet, it is proved to be excellent. The small footprint and big capacity of the spiral conveyor are what other kinds of conveyors can’t match.

“Give me a fulcrum, I can pry up the earth” Archimedes once said. Give spiral conveyor a bit of land, it makes the whole material handling system efficient and energetic–If you ask what’s the role of spiral conveyor in factory automation, it must be the best answer.