How to Judge If the Sag of Transmission Chain Normal or Not?

Tension regulation is indeed related to the length of the transmission chain, but they are two different concepts.A longish transmission chain doesn’t mean they lack of tension, but people are usually don’t want to see the sag of the chain. Actually, the tension will be reasonable if the chain can engage with the sprocket’s teeth well and can afford the load successfully.According to the above drawing, even 80 mm difference in sag will only reduce 1.5 teeth’engagement, so the length of chain is not key factor of tension.However, overlong chain will impact on the the engagement and brings insufficient wrapping [...]

Spiral Conveyor Has Become A Trend in Apparel Industry

Want to improve the efficiency of loading and automate your garment factory, but unsure of the solution and ROI? You may find the answer here. With the concentrated development of apparel industry, more and more garment processing factories are modernized and become large-scale. The growing demands for the production is an urgent question to be solved. Transporting the packaged garment from production area to warehouse or stocking area within minimal space & time is the most-asked requirements we received from customers in apparel industry. The solution is quite simple — NEXU Spiral Conveyor. Whether you have single-story space or multi-mezzanine [...]

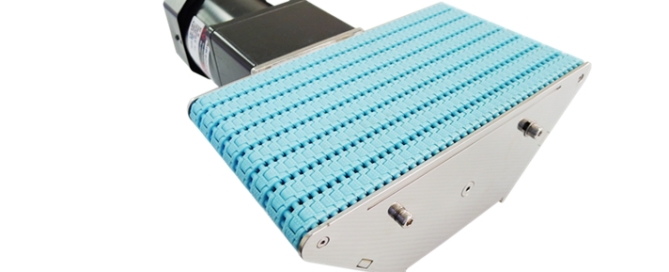

The First Mini Inclined Spiral Conveyor of NEXUS

This is the first set of Small Spiral Conveyor released. It has belt width of 165 mm and outer diameter of only 1365 mm, driven by a 0.25 KW SEW motor— This is NEXUS Narrow Track Spiral Conveyor. To satisfy our clients' needs for transporting objects with space limitations, we come out with a conveyor that takes smaller space but transports as effective and stable as the standard one does. This mini spiral conveyor is customized for a client in Malaysia. It is made from mild steel material and will be used to transport tea bag [...]

Which Kind of Transfer Conveyor is Suitable for My Production?

In the following two situations you usually need a transfer conveyor to realize the steady transmission of products: ● The objects are bottles, cans or other containers which are easy to fall/collapse because of small contact area on conveyor belt. ● Certain gap between conveyors, or between conveyor and other machine, such as feeding maching, packaging machine etc. so there is potential safety risk. A good transfer conveyor is also mobile conveyor, and has the following advantages: 1. It should be lightweight and portable, easy to achieve connection with other conveyors or machine. 2. With minimized roller diameter, which avoids [...]

FAT of NEXUS Dual Track Spiral Conveyors

This week two sets of NEXUS Dual track spiral conveyors are under FAT (Factory acceptance testing), both two spirals are stainless steel material with two 135 mm width tracks, double SEW brake motor. Max. speed of NEXUS dual track spiral conveyors is 60 M/min, the spirals operate well and the bottles are transported smoothly even when adjusting voltage frequency from 60 Hz to 80 Hz. Good quality and performance of these two dual track spirals get high satisfaction of the clients.